FILL-IZ 5000 CUP FILLING

Overview

FILL-IZ 5.000 Series provides custom–made solutions for reliable filling & closing pre–formed containers. Sturdy and proven mechanical design of the machinery within this series enables high speed linear operations.

The machines are built in a format of up to 6 lanes and are offered with double indexing systems which allows for both a fast format size change and a doubling of the machines output.

Thanks to the in-line and highly developed modular principle, the series allows a competitive, detailed and thorough response to the exact request of the customer.

Due to the long period of studying and researching conducted in R&D department, the series satisfies the most crucial needs whether these be demanding hygiene requirements, capacity requirements or the complex requirements of the product itself.

The CE marked FILL-IZ 5.000 series is manufactured by using stainless steel and equipment of high quality in order to provide the most hygenic solution for the required opetations.

Benefits

- Maximum speed and flexibility with servo controlled drive,

- Hygenic design,

- CIP operating system,

- Special design to provide Easy Maintenance possibility,

- All used equipments and material are suitable for working in wet environment,

- Complete stainles steel and food grade material execution,

- Maximum working security with close cabinet and lockable safety guards,

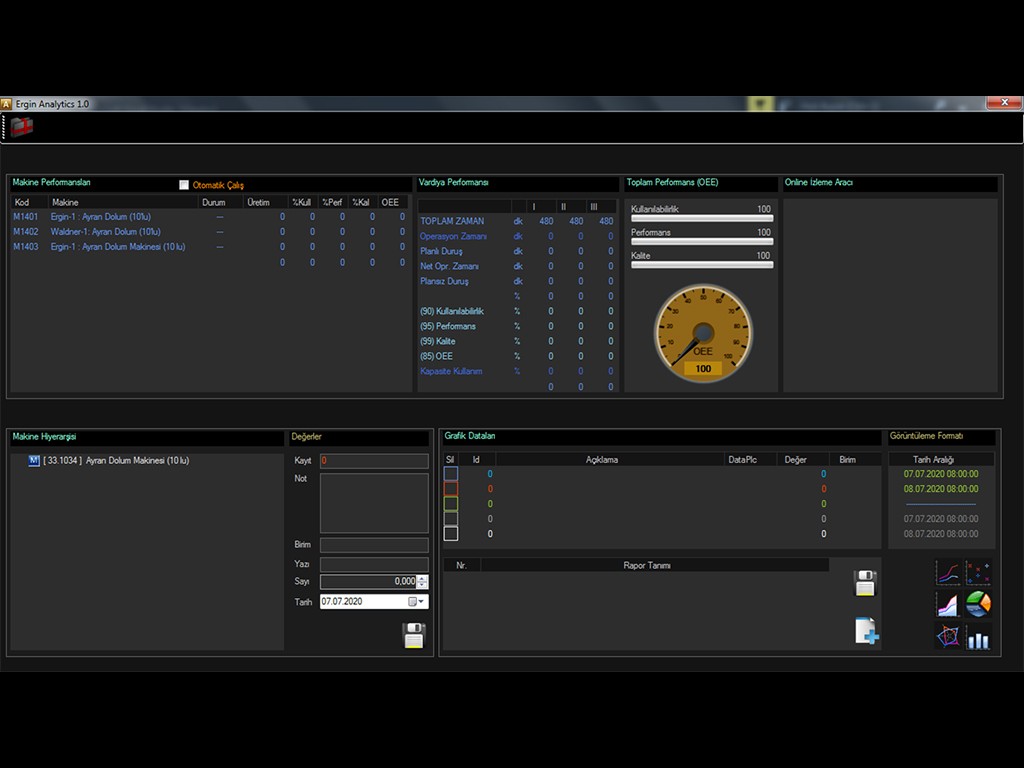

- User friendly display shows all functions and possible errors,

- Production recording possibility to increase machine efficiency,

- Internet assistance possibility.

Technical Data

| Number of Lines | Lines | 2 | 6 | 6×2 |

|---|---|---|---|---|

| Working Width | mm | 900 | 1.200 | 1.200 |

| Working Lenght | mm | 3.600 | 3.600 | 3.600 |

| Capacity-70ml | Pcs / Hour | 3.000 | 9.000 | 16.000 |

| Min. Dosing | ml | 20 | 20 | 20 |

| Max. Dosing | ml | 1.700 | 1.700 | 1.700 |

| Min. Cup Dimensions | mm | 160 | 160 | 160 |

| Min. Cup Height | mm | 150 | 150 | 150 |

Applications

-

DAIRY

- Yoghurt

- Yoghurt with Fruit

- Diluted Yoghurt

- Cream

- Cheese

- Cream Cheese

- Mozzarella

- Labne

- Curd

- Butter

- Kefir

- Ayran

- Quark

- Desserts

- Multi Fill Desserts

-

FRUIT &VEGETABLES

- Jam

- Marmalade

- Honey

- Pudding

- Mousse

- Chocolate

- Ketchup

- Sauces

- Tomato Paste

- Mustard

- Puree

-

FAT & OILS

- Margarine

- Shortening

- Mayonnaise

- Sunflower Oil

- Olive Oil

-

MEAL

- Ready Meals

- Salads

- Instant Soup

-

BEVERAGES

- Fruit Juice

- Lemonade

- Shakes

- Smoothies

- Coffee

Do you have any question?

Options

- External cup magazine

- Production Flexibility with the characteristic of double format execuiton

- Automatic magazine change

- H2O2 and UV-C cup sterilization

- CIP Operating system

- Sterile Pozitive Air

- Hepa H-14 Filter

- Burst contro / leakproofing test

- Sealing and cutting from film reels

- External cup magazine

- Integrated cup collection robot

- External Cup collection robot

- Automatic viol feeding unit

- Carton opening and closing units

- Wrap around cartoning system

- Filling by Multihead weigher

- Filling controlled by Flowmeter

- Volumetric filler controlled by Servo Motor

- Pneumatic controlled Volumetric Filler

- Volumetric Filler with reservoir

- Weight Controlled filler

- OVERVIEW

-

Overview

FILL-IZ 5.000 Series provides custom–made solutions for reliable filling & closing pre–formed containers. Sturdy and proven mechanical design of the machinery within this series enables high speed linear operations.

The machines are built in a format of up to 6 lanes and are offered with double indexing systems which allows for both a fast format size change and a doubling of the machines output.

Thanks to the in-line and highly developed modular principle, the series allows a competitive, detailed and thorough response to the exact request of the customer.

Due to the long period of studying and researching conducted in R&D department, the series satisfies the most crucial needs whether these be demanding hygiene requirements, capacity requirements or the complex requirements of the product itself.

The CE marked FILL-IZ 5.000 series is manufactured by using stainless steel and equipment of high quality in order to provide the most hygenic solution for the required opetations.

- BENEFITS

-

Benefits

- Maximum speed and flexibility with servo controlled drive,

- Hygenic design,

- CIP operating system,

- Special design to provide Easy Maintenance possibility,

- All used equipments and material are suitable for working in wet environment,

- Complete stainles steel and food grade material execution,

- Maximum working security with close cabinet and lockable safety guards,

- User friendly display shows all functions and possible errors,

- Production recording possibility to increase machine efficiency,

- Internet assistance possibility.

- TECHNICAL DATA

-

Technical Data

Number of Lines Lines 2 6 6×2 Working Width mm 900 1.200 1.200 Working Lenght mm 3.600 3.600 3.600 Capacity-70ml Pcs / Hour 3.000 9.000 16.000 Min. Dosing ml 20 20 20 Max. Dosing ml 1.700 1.700 1.700 Min. Cup Dimensions mm 160 160 160 Min. Cup Height mm 150 150 150 - APPLICATIONS

-

Applications

-

DAIRY

- Yoghurt

- Yoghurt with Fruit

- Diluted Yoghurt

- Cream

- Cheese

- Cream Cheese

- Mozzarella

- Labne

- Curd

- Butter

- Kefir

- Ayran

- Quark

- Desserts

- Multi Fill Desserts

-

FRUIT &VEGETABLES

- Jam

- Marmalade

- Honey

- Pudding

- Mousse

- Chocolate

- Ketchup

- Sauces

- Tomato Paste

- Mustard

- Puree

-

FAT & OILS

- Margarine

- Shortening

- Mayonnaise

- Sunflower Oil

- Olive Oil

-

MEAL

- Ready Meals

- Salads

- Instant Soup

-

BEVERAGES

- Fruit Juice

- Lemonade

- Shakes

- Smoothies

- Coffee

Do you have any question?

-

- OPTIONS

-

Options

- External cup magazine

- Production Flexibility with the characteristic of double format execuiton

- Automatic magazine change

- H2O2 and UV-C cup sterilization

- CIP Operating system

- Sterile Pozitive Air

- Hepa H-14 Filter

- Burst contro / leakproofing test

- Sealing and cutting from film reels

- External cup magazine

- Integrated cup collection robot

- External Cup collection robot

- Automatic viol feeding unit

- Carton opening and closing units

- Wrap around cartoning system

- Filling by Multihead weigher

- Filling controlled by Flowmeter

- Volumetric filler controlled by Servo Motor

- Pneumatic controlled Volumetric Filler

- Volumetric Filler with reservoir

- Weight Controlled filler

- VIDEO GALLERY

-

- PHOTO GALLERY

-

- DOWNLOAD