Overview

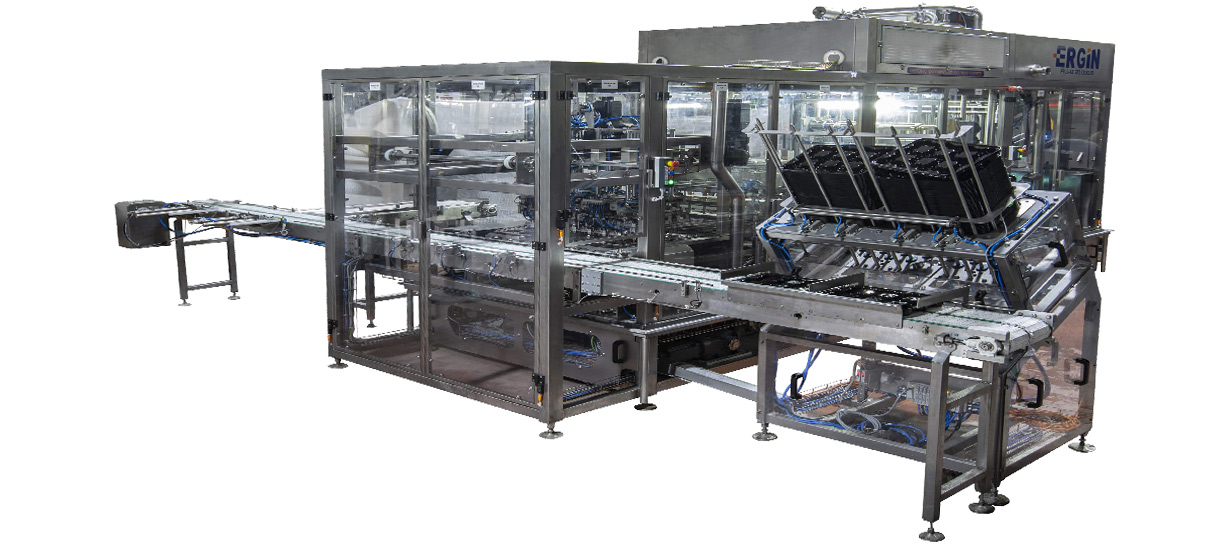

Conveyor systems which has been used in all our machieries, have been developed and produced over a long period of time. With the accumulated experience over the years, conveyor systems manufactured by Ergin Co. are enable to provide wide range of functions in order to respond the demands of including but not limited to food industries.

Operation speed of the conveyor systems has the ability to be arranged according to the tasks that is to be performed. The conveyor systems are designed for high efficiency and durability, coupled with minimal maintenance requirement, making it ideal for demanding environments, and allows ready accessibility.

Thanks to their simple yet reliable design the conveyor systems manufactured by Ergin Co. have the ability to adapt any kind of industrial envivorment.

Benefits

- Maximum speed and flexibility with servo controlled drive,

- Hygenic design,

- CIP operating system,

- Special design to provide Easy Maintenance possibility,

- All used equipments and material are suitable for working in wet environment,

- Complete stainles steel and food grade material execution,

- Maximum working security with close cabinet and lockable safety guards,

- User friendly display shows all functions and possible errors,

- Production recording possibility to increase machine efficiency,

- Internet assistance possibility.

Technical Data

| Number of Lines | Lines | 1 | 2 |

|---|---|---|---|

| Working Width | mm | 1.400 | 1.400 |

| Working Lenght | mm | 2.500 | 4.800 |

| Capacity | Pcs / Hour | ||

| Max. Cup Dimensions | mm | 95 | 95 |

Applications

-

DAIRY

- Yoghurt

- Yoghurt with Fruit

- Diluted Yoghurt

- Cream

- Cheese

- Cream Cheese

- Mozzarella

- Labne

- Curd

- Butter

- Kefir

- Ayran

- Quark

- Desserts

- Multi Fill Desserts

-

FRUIT &VEGETABLES

- Jam

- Marmalade

- Honey

- Pudding

- Mousse

- Chocolate

- Ketchup

- Sauces

- Tomato Paste

- Mustard

- Puree

-

FAT & OILS

- Margarine

- Shortening

- Mayonnaise

- Sunflower Oil

- Olive Oil

-

MEAL

- Ready Meals

- Salads

- Instant Soup

-

BEVERAGES

- Fruit Juice

- Lemonade

- Shakes

- Smoothies

- Coffee

Options

- External cup magazine

- Production Flexibility with the characteristic of double format execuiton

- Automatic magazine change

- H2O2 and UV-C cup sterilization

- CIP Operating system

- Sterile Pozitive Air

- Hepa H-14 Filter

- Burst contro / leakproofing test

- Sealing and cutting from film reels

- External cup magazine

- Integrated cup collection robot

- External Cup collection robot

- Automatic viol feeding unit

- Carton opening and closing units

- Wrap around cartoning system

- Filling by Multihead weigher

- Filling controlled by Flowmeter

- Volumetric filler controlled by Servo Motor

- Pneumatic controlled Volumetric Filler

- Volumetric Filler with reservoir

- Weight Controlled filler